How Are Wireless Motion Detectors Made in a Factory?

Wireless motion detectors have become an essential part of modern security systems, providing reliable and efficient protection for homes and businesses. These devices detect movement within a specific range and trigger an alert, helping to prevent unauthorized access and increase safety. If you’ve ever wondered how these devices are made, you're not alone. In this article, we’ll explore the manufacturing process behind wireless motion detectors, focusing on how motion detector sensors are produced in a factory setting. We’ll also highlight how Sunlit-Tech, a leading brand in the security industry, ensures the quality and functionality of their products.

Step 1: Design and Development

The first stage in manufacturing a wireless motion detector is the design and development phase. This involves:

- Product Conceptualization: Engineers and designers work together to develop a concept that meets customer needs. This includes determining the size, functionality, and aesthetics of the motion detector.

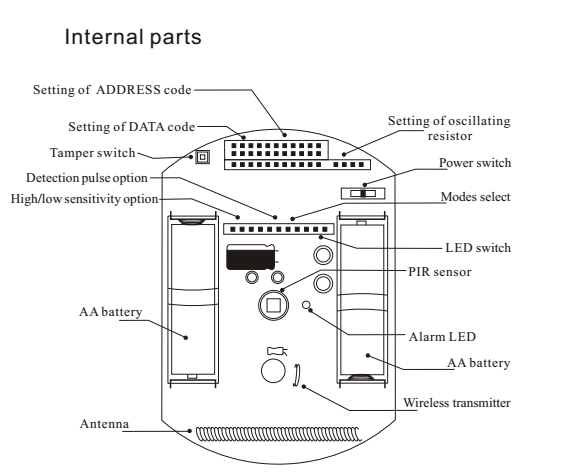

- Choosing the Right Components: For a motion detector sensor, the key components include the sensor itself (such as a Passive Infrared (PIR) sensor), the microcontroller, communication modules (like WiFi or Bluetooth), and a power source (usually batteries or rechargeable lithium-ion cells).

- Prototyping: A prototype is created to test how the motion detector functions in real-world conditions. This helps identify any potential flaws or areas for improvement before moving forward with full-scale production.

Sunlit-Tech invests heavily in this phase to ensure that the product design is not only user-friendly but also energy-efficient and long-lasting.

Step 2: Sourcing Materials and Components

Once the design is finalized, the next step is sourcing the materials and components required for the production of the wireless motion detectors. This includes:

- Sensors: The core of any motion detector is its sensor. For motion detector sensors, manufacturers typically use PIR (Passive Infrared) technology to detect heat changes caused by human or animal movement. The sensor needs to be sensitive enough to detect movement but not so sensitive that it generates false alarms.

- Communication Modules: Wireless motion detectors rely on communication modules such as WiFi, Zigbee, or Bluetooth to send alerts or communicate with other devices in the security system. The module selected must be compatible with the intended system.

- Microcontroller: This is the "brain" of the motion detector. It processes the data from the sensor and determines whether an alert should be triggered. It also manages the wireless communication.

- Casing and Housing: The casing protects the internal components and is usually made of high-quality plastic or ABS material. It is designed to withstand wear and tear, environmental factors, and physical impact.

Sunlit-Tech ensures that every component meets the highest quality standards, ensuring the reliability and durability of each motion detector sensor.

Step 3: Assembly of Components

With the components sourced, assembly begins. This step is where the magic happens and involves several key stages:

- Sensor and Circuit Assembly: The PIR sensor, microcontroller, and other circuit elements are mounted onto a printed circuit board (PCB). This is typically done using automated machines that place and solder the components in place.

- Wireless Module Integration: The communication module is then integrated into the system. For wireless motion detectors, this is a critical step, as it ensures that the device can effectively communicate with the rest of the security system.

- Power Source Installation: The power source is installed and connected, ensuring that the motion detector is energy-efficient. For many wireless motion detectors, this is a battery-operated system, though some models can be recharged.

At Sunlit-Tech, assembly is done with precision to ensure the internal wiring and connections are solid, minimizing the risk of malfunctions.

Step 4: Testing and Quality Control

Once the assembly is complete, the next step is thorough testing and quality control. This stage ensures that the motion detector sensor works as intended and meets all the required specifications. Common tests include:

- Functional Testing: Each wireless motion detector is tested to ensure it detects motion accurately within its specified range. The communication module is also tested to ensure it can send signals or notifications to connected devices, such as a smartphone or home security hub.

- Range and Sensitivity Testing: The detection range and sensitivity of the PIR sensor are tested to ensure the detector responds to the right level of movement without triggering false alarms.

- Environmental Testing: The device is subjected to various environmental conditions such as temperature, humidity, and even simulated vibrations to make sure the motion detector will work reliably under real-world conditions.

- Battery Life Testing: Since many wireless motion detectors are battery-powered, it’s important to test battery life to ensure the product is energy-efficient and can last for extended periods.

Sunlit-Tech emphasizes strict quality control procedures throughout this stage to ensure every unit meets industry standards and customer expectations.

Step 5: Packaging and Distribution

Once the motion detectors have passed all the tests, they are packaged and prepared for shipment. During the packaging process:

- Final Inspections: Each unit undergoes a final inspection to ensure there are no defects or issues.

- Instruction Manuals: An instruction manual is included in the packaging to help users set up and configure the wireless motion detector easily.

- Packaging for Shipment: The motion detectors are then carefully packed in protective materials to prevent damage during transport.

After packaging, the products are shipped to distributors, retailers, or directly to consumers.

Why Choose Sunlit-Tech for Your Wireless Motion Detectors?

Sunlit-Tech is committed to providing high-quality, reliable wireless motion detectors designed to meet the demands of modern security systems. Their motion detector sensors undergo rigorous testing and are made from premium components, ensuring performance, durability, and long-lasting use. Whether you're looking for home security, office protection, or industrial applications, Sunlit-Tech offers a range of motion detectors that integrate seamlessly into existing security systems, providing real-time alerts and peace of mind.

Conclusion:

The manufacturing process of wireless motion detectors involves careful planning, sourcing, assembly, and testing. From selecting the right motion detector sensor to ensuring each unit is tested for accuracy and reliability, the process requires precision and attention to detail. Brands like Sunlit-Tech are dedicated to producing top-tier motion detectors that offer effective security solutions for homes, businesses, and more. By investing in high-quality products, consumers can feel confident that their property is protected by a robust and reliable motion detection system.www.zn-bio.com ;www.zwintelligent.com

简体中文

简体中文